Surface Deburring Holder C10

Movie

Product features

Simple deburring holder that can be used for NC machines, robots, and various special machines

Inexpensive simplified deburring holder has the mechanism of contracting 10mm only in the axial direction.

A built-in mechanism of contracting 10mm only in the axial direction

The holder has a built-in mechanism of contracting 10mm and can deburr the surface side by constantly pressurizing the cutting edge.

Three kinds of spring that have different strength are provided as standard

The holder includes 3 springs with different strengths as standard accessories. The internal springs can be changed as desired to match the material of the workpiece to process.

Top rated speed of 10,000min-1

Top rated speed of 10,000min-1. When using this holder for a machining center, attach the holder to the mealing chuck.

Applicable machine: machining center, robot system and special machines

Dimensions ( Unit : mm )

| Model | Shank diameter | L1 | L2 | L3 | C | D | E | H | F1 | Unit weight | Fig |

|---|---|---|---|---|---|---|---|---|---|---|---|

| C10-10 | 10 | 126 | 45 | 35 | 10 | 16 | 23 | 7 | 10 | 0.18 | 1 |

| C10-20 | 20 | 112 | 75 | 40 | 20 | 16 | 25 | 13 | 10 | 0.22 | 2 |

| C10-32 | 32 | 123 | 80 | 43 | 32 | 22 | 36 | 27 | 10 | 0.53 | 2 |

| C10-20L | 20 | 172 | 135 | 100 | 20 | 16 | 25 | 13 | 10 | 0.35 | 2 |

| C10-32L | 32 | 180 | 137 | 100 | 32 | 22 | 36 | 27 | 10 | 0.82 | 2 |

- The holder has a top rated speed of 10,000min-1. Attach the holder to your milling chuck when you use it with a machining center.

- The collet at the tip has a proven DIN standard 16° taper.

- The gripping range of the collet is φ0.5 to φ7mm for ER11, and φ0.5 to φ10mm for ER16. *Requires a collet that matches the gripping size (sold separately).

- Use a hexagonal wrench to loosen the M4 set screw and hold the two sides of the H dimension to remove the adjusting nut. You can change the springs easily by replacing the internal spring with one of the other provided standard springs, retightening the adjusting nut, and fastening the M4 set screw. *The C10-10 model does not have an M4 set screw.

- The holder is designed exclusively for deburring. Do not use it for other applications.

- Avoid fastening too tightly when attaching a shank to a milling chuck. Use the fastening torque recommended by the milling chuck manufacturer.

- Do not use this product with a side lock holder. Note that fastening from a single direction can cause shank deformation and stop the movement of the sliding portion.

Included Accessories ( Unit : mm )

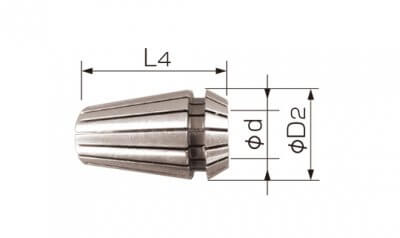

ER taper collet

Each holder comes with an ER11-φ6 and an ER16-φ6 collet.

| Model | Collet Type | Axial diameter φd | L4 | φD2 | Dedicated nut |

|---|---|---|---|---|---|

| C10-10 | ER11-φ6 | 6.0 | 18.0 | 11.5 | ERM11 |

| C10-20 | ER11-φ6 | 18.0 | 11.5 | ERM11 | |

| C10-32 | ER16-φ6 | 27.5 | 17.0 | ERM16 | |

| C10-20L | ER11-φ6 | 18.0 | 11.5 | ERM11 | |

| C10-32L | ER16-φ6 | 27.5 | 17.0 | ERM16 |

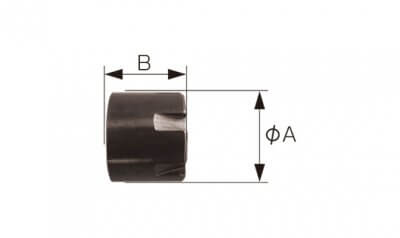

ERM nut

Each holder comes with an ERM11 and an ERM16 nut.

| Model | Nut type | A | B | Dedicated spanner |

|---|---|---|---|---|

| C10-10 | ERM11 | 16.0 | 12.0 | E11M |

| C10-20 | ERM11 | 16.0 | 12.0 | E11M |

| C10-32 | ERM16 | 22.0 | 18.4 | E16M |

| C10-20L | ERM11 | 16.0 | 12.0 | E11M |

| C10-32L | ERM16 | 22.0 | 18.4 | E16M |

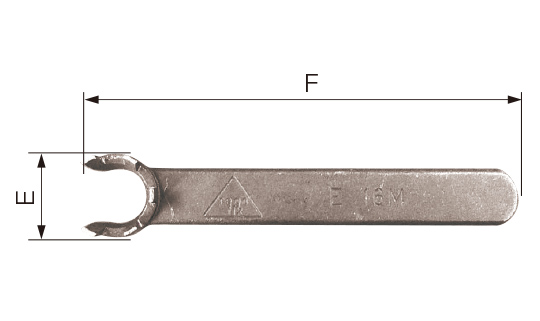

Dedicated spanner for the C10 series

Each holder comes with an E11M and an E16M spanner.

| Model | Nut type | E | F |

|---|---|---|---|

| C10-10 | E11M | 17.5 | 102.5 |

| C10-20 | E11M | 17.5 | 102.5 |

| C10-32 | E16M | 22.5 | 117.5 |

| C10-20L | E11M | 17.5 | 102.5 |

| C10-32L | E16M | 22.5 | 117.5 |

Notice: Before Ordering

- This holder can use for NC machines, robots, and various special machines.

- When using this holder for a machining center, attach the holder to the mealing chuck.

- When using this holder for a robot and various special machines, prepare a dedicated mounting holder (side lock holder or collet holder).

Applications

This holder is used for removing burrs made in machining (perforating, end mill processing, face mill processing, etc.) as well as burrs on the outer and inner parts such as casted burrs, forged burrs, and plastic-molded burrs.

Special Features and Usage Warnings

- The C10 features a function that the tip (cutting tool gripper) contracts 10mm in the axial direction.

- With the functions mentioned above, the holders can deburr by absorbing some misalignment of a work set on the machine in the axial direction.

- The holders have the top rated speed of 10,000 min-1, which allows the use of a superhard cutting tool (rotary bar) the most appropriate for deburring.(Never use the deburring holders by the number of revolutions that exceeds the top rated speed.)

- When using this holder, ensure that the bit basically approaches the works with a down cut.

Precautions when deburring

When using this unit for a deburring job, if the bit approaches the works and processing begins with an up cut at the corner section, the bit may catch and snarl on the corner section.

When starting a job from a corner section, ensure that your processing program begins the approach with a down cut.

When choosing a bit, you must consider several factors, including the special features provided by the unit, as well as the work materials, work-mounting method, and the shape of the section to be deburred.

If you are unsure of which is the best bit to use, please consult with our staff or your retailer.