Research and development of proprietary automated deburring technology

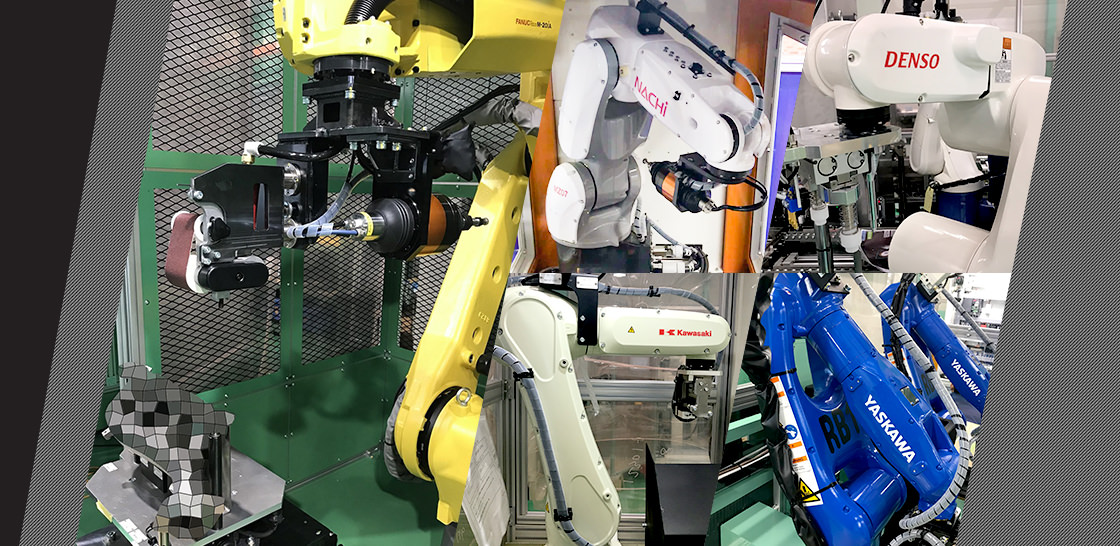

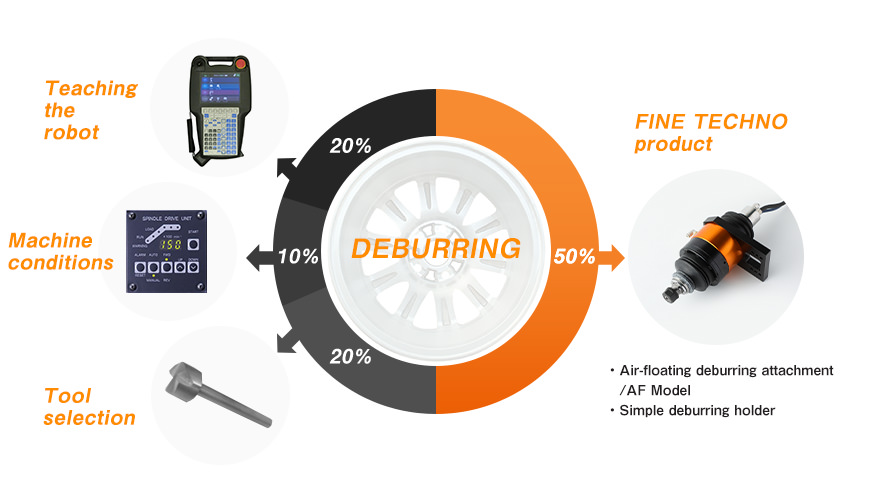

FINE TECHNO’s business specializes in the automation of deburring processes, with a focus on the development, design, fabrication, and sale of automated deburring systems and deburring holders and tools.

The requirements in the field of deburring automation become ever more sophisticated and diverse due to growing demand for higher quality in production processes, cost-cutting efforts, worker shortages, and other issues. Amid this trend, we have placed repeated efforts into research and development that has allowed us to realize automated deburring technology that is on a par with the fast, high-quality work of skilled technicians.